Disposable vapes have become very popular lately. They come with stylish looks and many exciting flavors that give smooth and steady hits. These devices usually feature easy-to-use designs and offer plenty of different tastes, from sweet fruit explosions to gentle tobacco hints. The main thing that makes them so enjoyable is the e-liquid, also called vape juice, inside. Still, most users have no idea where this important part actually comes from.

The truth is simple: more than 95% of disposable vapes sold around the world are made in Shenzhen, China – a city often called the “High-Tech Hardware Hub.” This place used to be famous for building the best smartphones on the planet. Now it has turned into the biggest and most complete center for the whole e-cigarette business. Almost all the creative e-liquids used in these devices are mixed right here, inside modern factories built for accuracy and large-scale output.

Most brands that sell disposable vapes do not make anything themselves. Instead, they work with expert factories that handle both the device building and the vape juice creation. The brands focus only on marketing and selling.

For example, the vape juice found in many well-known disposables is supplied by special companies located. There, huge industrial areas make everything work together smoothly.

Why Does All the E-Liquid Come from Shenzhen?

Shenzhen leads in e-liquid making because it can bring every single step of vape production together in one area. This covers batteries, circuit boards, heating parts, atomizers, oil tanks, and of course the e-liquid itself. Having everything close together makes the whole process faster and more efficient.

E-liquid factories are often just a short drive away from the places that put the hardware together. This setup was planned on purpose. It copies the same system that made Shenzhen the king of smartphones. Now that system works even better for vaping and helps teams improve both the devices and the liquids at the same time.

The outcome is clear. Products move quickly from idea to store shelves. Disposable vapes reach customers with flavors that stay strong and reliable for thousands of puffs.

What Is E-Liquid Manufacturing Engineering?

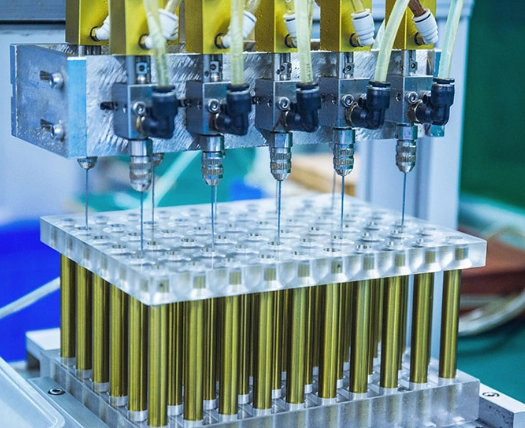

Real professional e-liquid production is completely different from mixing flavors at home. It needs strict control of every ingredient, lots of testing rounds, careful processing steps, and advanced machines. Top factories spend millions on CNAS-certified labs to keep quality and safety high.

Everything starts in the research and development department. Teams study market trends and device details to plan new flavors. Skilled flavorists – usually people trained in chemistry or food science – choose from huge collections of aroma compounds. They test and adjust the recipe hundreds of times until the taste stays stable, strong, and perfect for the device’s heating system.

Making great vape juice is just as complex as building the device itself. It combines knowledge from organic chemistry, food chemistry, formulation science, flavor creation, and taste testing. Every batch gets exact measurements to reach the right PG/VG ratio – propylene glycol gives the throat hit while vegetable glycerin creates thick vapor. Nicotine salts are added for a smoother feel, especially in disposables.

This careful engineering makes sure the e-liquid resists going bad, keeps the same great taste for a long time, and produces very few unwanted chemicals.

Four Key Advantages of Chinese E-Liquid Manufacturers

Chinese e-liquid makers, especially those in Shenzhen, stand out because of strong systems and smart operations help the entire disposable vape industry.

R&D Capability

E-liquid experts work side by side with hardware teams. They create flavors that match perfectly with device parts for the best wicking and vapor. Customer feedback drives fresh ideas like cool summer fruit mixes or light tobacco options. Deep understanding of how ingredients behave inside devices helps prevent problems before production even starts.

Manufacturing Efficiency

Everything stays close together – raw materials, packaging, and shipping. This cuts waiting time from weeks down to days. Modern computer systems, built on Shenzhen’s tech strength, control every step with precision. Flexible lines can switch quickly from small test batches to massive runs, perfect for disposable vapes that need huge numbers fast.

Cost Advantage

A large group of trained workers keeps costs fair. China leads the world in making pure aroma compounds at good prices. Being next to major ports makes export cheaper and faster for disposable vape markets everywhere.

Comprehensive Services

Complete OEM/ODM packages cover flavor creation, lab tests, filling, labeling, and packing. This makes launching a new brand much easier. Extra help like market reports, branding advice, and rules guidance – including TPD compliance and emissions tests – lets customers meet global requirements without stress.

These strong points, well-practiced advantages make Shenzhen factories essential for top-quality disposable vape e-liquid.

Where Does the Trust Come From?

People trust Shenzhen e-liquids because factories follow strict global rules such as ISO 9001 for quality control, GMP for clean production, and HACCP for safety checks. Clean rooms without dust, robot filling machines, and regular audits keep every single unit exactly the same.

New government rules from China’s State Tobacco Monopoly Administration have made inspections tougher. Bad factories get closed, and only the best ones keep exporting. Yearly clean-ups remove unlicensed companies and raise the overall standard. This means disposable vape juices stay pure and pure with correct labels.

Simple QR-code scans let anyone check where a batch was made. All these steps not only meet world standards – they often go beyond them, bringing real confidence to a market that used to have many doubts.

The Power of Integrated E-Liquid and Vape Device Development in One Factory

In the disposable vape world, the strongest advantage is keeping both e-liquid creation and device design inside the same company. This removes waiting, wrong matches, and quality drops that always happen when different suppliers work separately.

Inside Shenzhen’s system, fully integrated manufacturers build e-liquids made exactly for their own mesh coils, airflow paths, battery power curves, and tank materials. When engineers improve a coil or change the chamber, the flavor team next door can adjust the liquid the same day. Together they reach perfect wicking speed, no leaks, steady nicotine over 3000–10000 puffs, and zero loss of taste.

The final product delivers perfect performance from the very first draw until the last, with thick clouds and steady flavor that outside suppliers simply cannot equal in speed or accuracy.

VEIIK shows this integrated approach perfectly. Located in Shenzhen Bao’an District, VEIIK makes both pharmaceutical-grade e-liquids and its complete line of disposable devices in the same facilities. From nicotine salt recipes to mesh-coil models like the Micko series, every liquid matches VEIIK hardware exactly. This brings outstanding performance and dependability for OEM/ODM partners all over the world.

This full control is why phrases like “in-house e-liquid + device co-engineering” and “full-chain vape manufacturing” have become the new global benchmark for speed, stability, and value.

FAQ

What percentage of disposable vapes are manufactured in Shenzhen, China?

Over 95% of disposable vapes worldwide are produced in Shenzhen, recognized as the global epicenter for e-cigarette manufacturing.

Why is Shenzhen ideal for e-liquid production?

Shenzhen’s integrated ecosystem unifies all vape components, enabling efficient, high-volume production with proximity between factories for reduced lead times.

What standards do Chinese e-liquid manufacturers follow?

They adhere to international certifications including ISO 9001, GMP, and HACCP, with cleanroom facilities and rigorous testing for consistency and safety.

How is high-quality vape juice formulated?

Formulation involves R&D with flavorists selecting from thousands of compounds, conducting hundreds of iterations, and testing for stability and device compatibility.

What are the main advantages of partnering with Shenzhen e-liquid factories?

Key benefits include advanced R&D, manufacturing efficiency, cost savings, and comprehensive OEM/ODM services tailored for disposable vape brands.

Partner with VEIIK – Your Trusted Integrated E-Liquid & Vape Device Manufacturer and Supplier

As a leading vape manufacturer, supplier, and factory specializing in both e-liquids and disposable vape devices, VEIIK invites OEM/ODM partners to leverage Shenzhen’s premier ecosystem for custom formulations and integrated production. Explore tailored e-liquid solutions, from flavor development to full-scale filling, designed to elevate disposable vape lines with certified quality and rapid turnaround. Contact the VEIIK wholesale team at wholesale@veiik.com or +86 15814728360 to discuss bulk orders, compliance support, and exclusive co-development opportunities that drive global success.